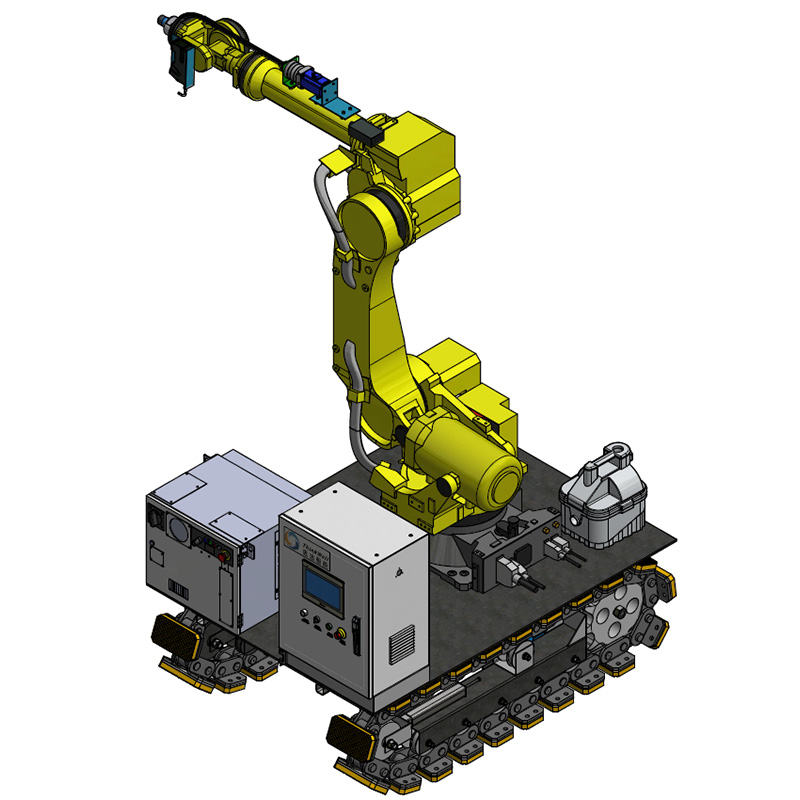

Automatic Blade Split-Layer Grinding Equipment

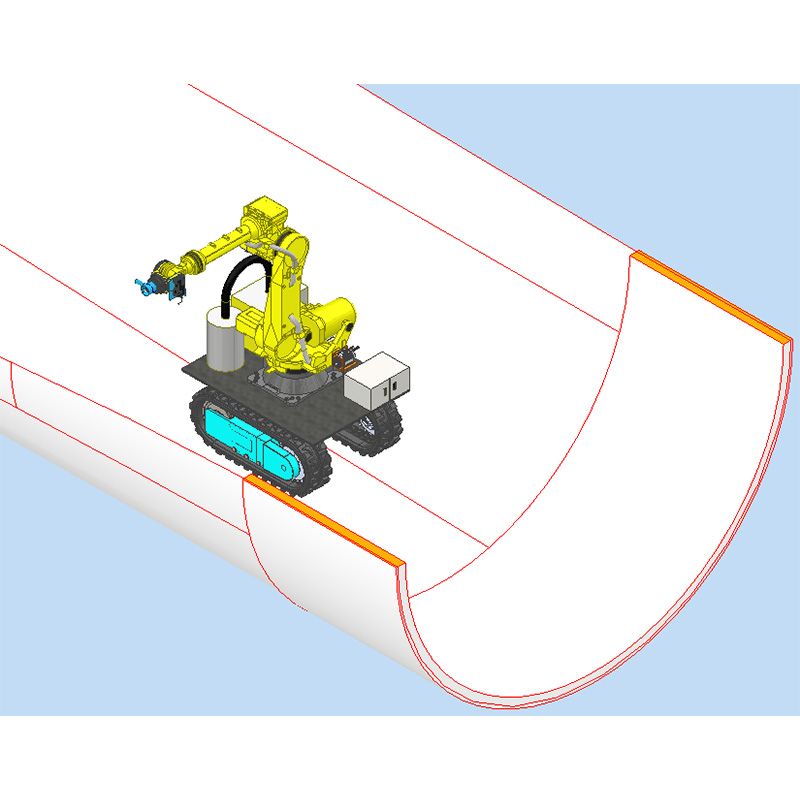

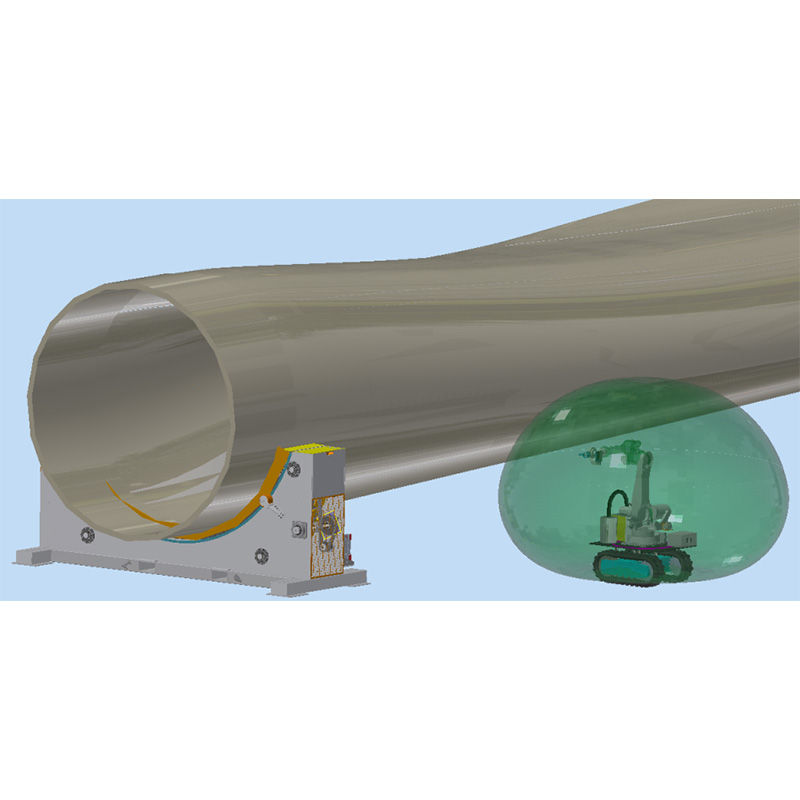

The automatic blade split-layer grinding equipment breaks through the traditional grinding ideas, the grinding head moves flexibly, it has 6 degrees of freedom in the space, and its grinding trajectory can be polished with the change of the blade shape, the whole machine can move flexibly and can walk automatically without multiple hoisting.

1. Short preparation time, the equipment can move when powered on, and can automatically continue to move when powered off, with a endurance time of 2 hours. The outer surface of the blades can be polished without lifting, and the equipment can be driven to the polishing position for polishing without much preparation time. The polishing of the inner surface of the blade only requires lifting once, and the equipment can walk and polish the inner surface. The preparation time for the first polishing of the inner surface is less than 10 minutes, and no preparation time is required for the second polishing.

2、Short scanning time with high accuracy, the end of the manipulator is equipped with high-precision line laser scanning, the scanning speed is ≥0.5m2/min, Through software and algorithms, surface foreign object interference can be avoided, outliers can be removed, and the contour of the surface to be polished can be extracted. The scanning contour degree is ≤0.2mm.

3、High milling speed, high precision, the end of the high-precision six-axis robot is equipped with a vertical milling cutter to mill the surface, the end movement speed is adjustable, the maximum speed of milling speed is ≥0.05m2/min, the end of the robot can load 165kg, the end positioning accuracy is 0.05mm, the cumulative grinding accuracy of the equipment is ≤0.1mm, and the milling profile is ≤0.2mm; The single milling thickness is 0.2mm, and the milling thickness is adjustable.

4、The working environment is good, the equipment is equipped with a high adsorption industrial dust collection system, the brush installed on the surface of the grinding head head to fully contact the polishing surface, adsorb the grinding debris, and the dust concentration detector is installed on the surface of the working head to control the dust concentration of the equipment ≤ 1mg/m³.

5、High processing efficiency, the equipment can control the end milling of the six-axis robot, The arm span of the six axis robot is 2.6m, which can cover a large grinding range, the number of grinding layers is ≥ 20 layers, the grinding height can cover the height of 0.5-3.5m, and the single grinding area is ≥1m*1m.

6、High safety, safety gratings are installed on both sides of the equipment, and if someone or something approaches the safety grating ,the equipment will automatically stop.

7、High degree of automation, the equipment only needs to be operated by one person, automatic scanning, positioning, grinding, except for walking, all other operations do not require manual operation.

No. | Item | Technical Parameter |

1 | Length | 2000mm |

2 | Width | 1.5mm |

3 | Weight | 2.2t |

4 | Grinding power | 0.75kw |

5 | Grinding head speed | 750r/min |

6 | Rated power consumption of robot | 2.5kw |

7 | Chassis power | 6kw |

8 | Suction power | 1kw |

9 | Grinding speed | ≥0.05m2/min |

10 | Single grinding area | ≥1m*1m |

11 | Number of grinding layers | >20 |

12 | Grinding height | 0.5m-3.5m |

13 | Grinding precision | ≤0.1mm |