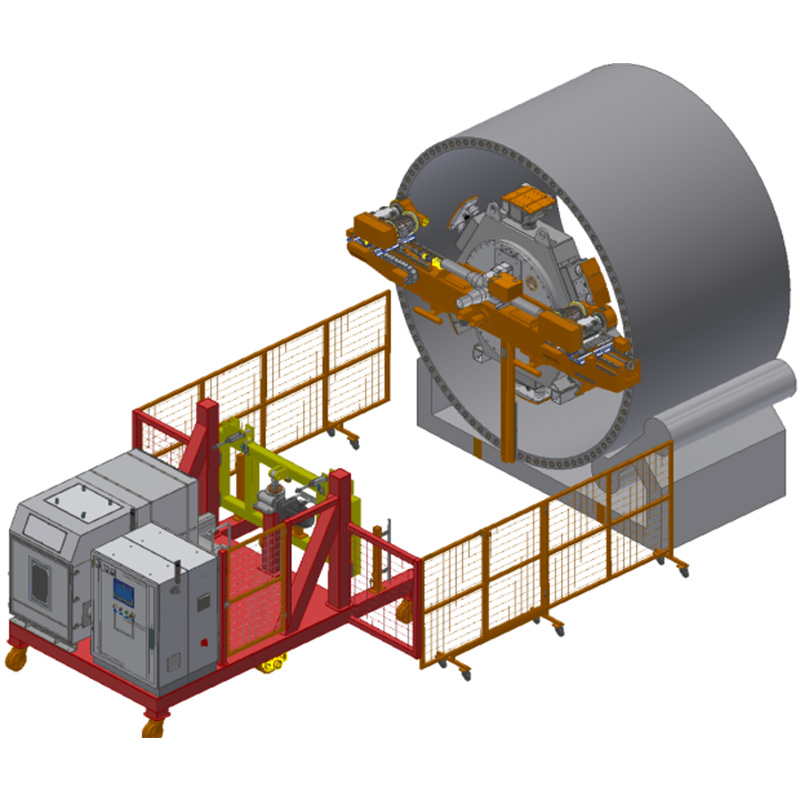

Self-Moving Intelligent End Milling Machine

The sixth generation self-moving intelligent root miller is the latest product developed by Hunan ThinkWell. This equipment adds a self-moving trolley with lifting adjustment function, which can complete handling and miller installation without the need for a crane or other auxiliary equipments.The equipment handling and positioning are operated by a remote control, and one person can complete the handling, installation, and milling work without any risk of climbing. It can also be operated outdoors to meet the different usage needs of customers in different scenarios. This equipment solves the problem of no crane lifting in the customer's workshop and the need to switch between multiple workstations. At the same time, it solves the safety risks during lifting and handling, greatly improving production efficiency and reducing production costs.

1.High machining precision, the highest plane machining precision reaches 0.12mm, far exceeding the precision of other milling equipment in the same industry.

2.High positioning accuracy, using intelligent algorithms, automatically find the best parallel plane with the leaf root for positioning, with minimum machining allowance.

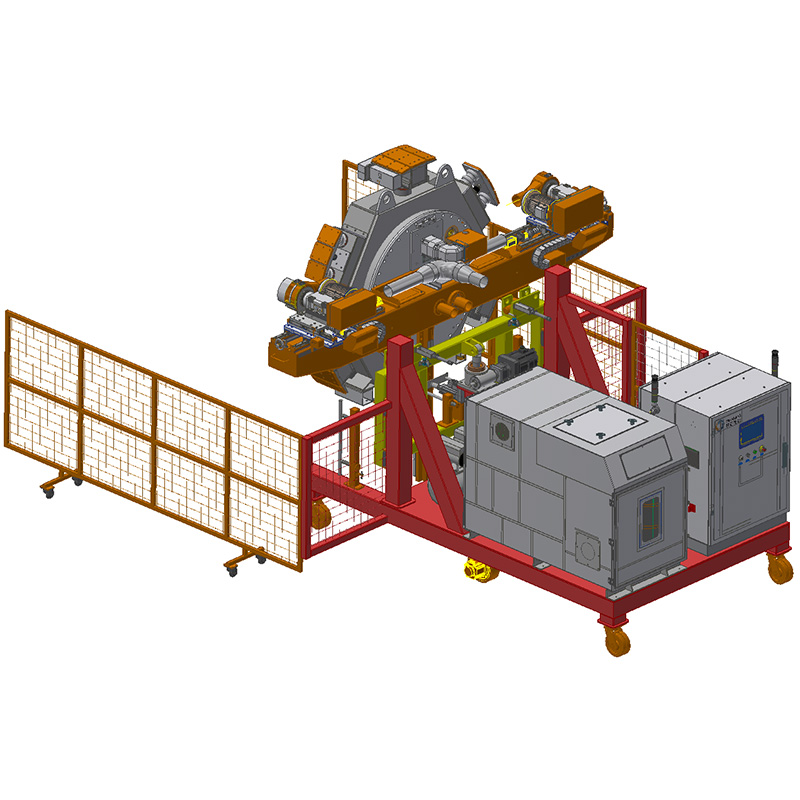

3.High safety performance, internal rise type positioning, support leg with load, displacement and torque monitoring and protection at the same time, positioning safety and reliability.

4.High machining efficiency, frequency conversion dual spindle simultaneous processing, efficiency is more than 5 times higher than grinding wheel grinding.

5.High-precision self-inspection, to ensure that each blade after processing is a qualified product, saving inspection costs and time for customers.

6.Traceable data, all measurement data and operation records are stored according to the number of the blade, which is convenient for future statistical inquiries.

7.More friendly environment, equipped with high efficient dust removal system, high efficiency of removing iron chips and dust, on-site hygiene and safety.

8.Compatible with a wide range, can be compatible with several different pitch circle blades at the same time, fast switching speed, reduce equipment procurement costs.

9.Specialized blades can mill bolt sets and fiberglass at the same time, with long service life and low cost of consumables.

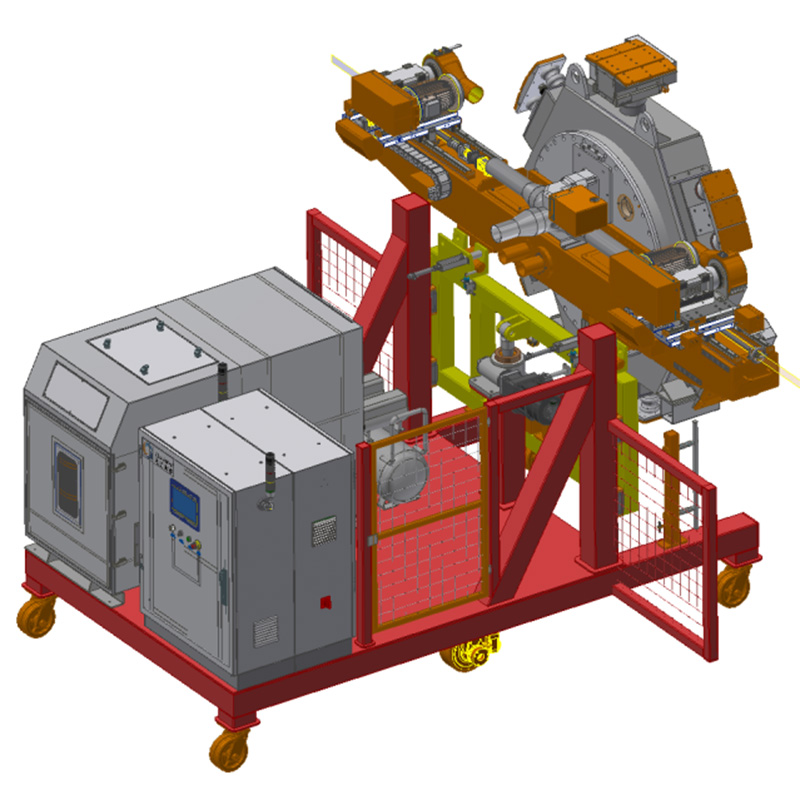

10.Low work intensity, no need to ascend, that is, can complete the equipment lifting and positioning, and equipped with maintenance platform, easy maintenance.

11.Remote control mobile: the self-moving trolley is equipped with AGV steering wheels, making it easy to move. The mobile endurance is 2 hours, and it automatically charges.

12.Laser line positioning: In the front and back directions of the equipment , there are contour laser positioning lights on the ground, making it convenient for operators to recognize the position.

13.Low maintenance cost, only need to clean and grease regularly.

NO. | Item | Technical Parameter |

1 | Applicable blade pitch specifications | Φ2300mm ~3200mm | Φ4600mm ~5600mm |

2 | Flatness accuracy | 0.25~0.4mm | ~0.5mm |

3 | Spindle radial adjustment range | 0~600mm | 0~600mm |

4 | Spindle axial adjustment range | 0~70mm | 0~70mm |

5 | Processing spindle power | 3Kw+3Kw | 3Kw+3Kw |

6 | Cutter head diameter | Φ160mm | Φ200mm |

7 | Maximum rotation speed | 0.25rpm | 0.25rpm |

8 | Maximum rotation angle | ≥400° | ≥400° |

9 | Lifting speed | 125mm/min | 125mm/min |

10 | Lifting height | 0~450mm | 0~1000mm |

11 | Movement speed | 60m/min | 60m/min |

12 | Angle adjustment range | ±5° | ±5° |

13 | Endurance | 2h(Battery selection) | 2h(Battery selection) |

14 | Power | 20Kw | 20Kw |

15 | Equipment Weight | 6000Kg | 8000Kg |

16 | Equipment size(L*W*H) | 4000mm*3400mm*3000mm | 4000mm*6000mm*5000mm |