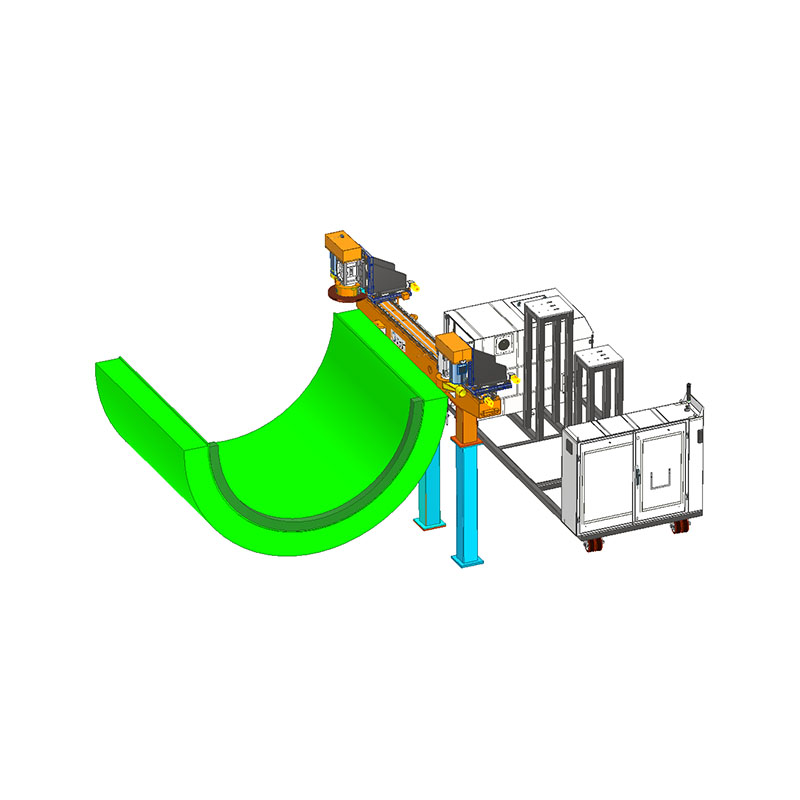

1.High machining accuracy,the flatness after milling can reach within 0.5mm;

2.High processing efficiency,cutting first and then milling,completing unilateral processing within 30 minutes;

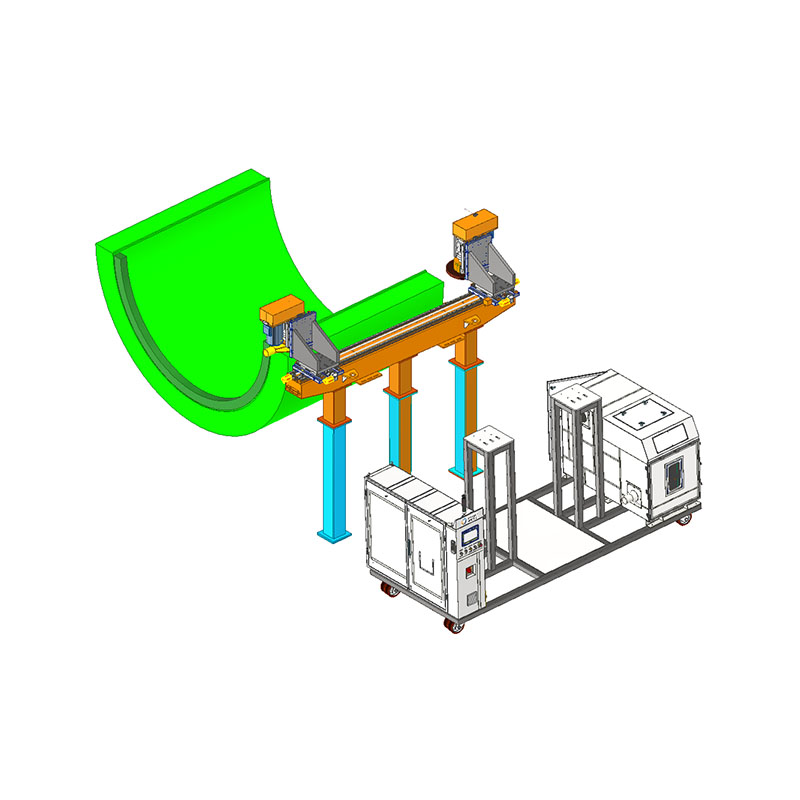

3.Fast positioning speed,guided positioning by inserting legs,convenient locking,and easy disassembly and assembly;

4.Good dust removal effect,equipped with a large flow and high negative pressure dust collector,dust collection can reach over 98%;

5.Convenient operation,automatic processing,and manual remote control operation;

6.Automatic inspection,after milling is completed,can accurately measure the machining height and plane accuracy of the blade root,and generate a report;

7.Convenient to move,equipped with a mobile trolley that can be pulled by a forklift or lifted by a crane to move the equipment;

8.The operation interface is powerful,allowing for process settings,automatic/manual operations,measurement data viewing,fault alarm information viewing,report generation,and more.