Equipment Of Intelligent Laying Glass Fiber Cloth Mould Of Blade Beam

The equipment is a kind of intelligent spreader. It's easy to operate, accurate to control, and can improve the accuracy and effect of spreader which can also improve production efficiency, reduce production cost and create good economic benefits for enterprises.

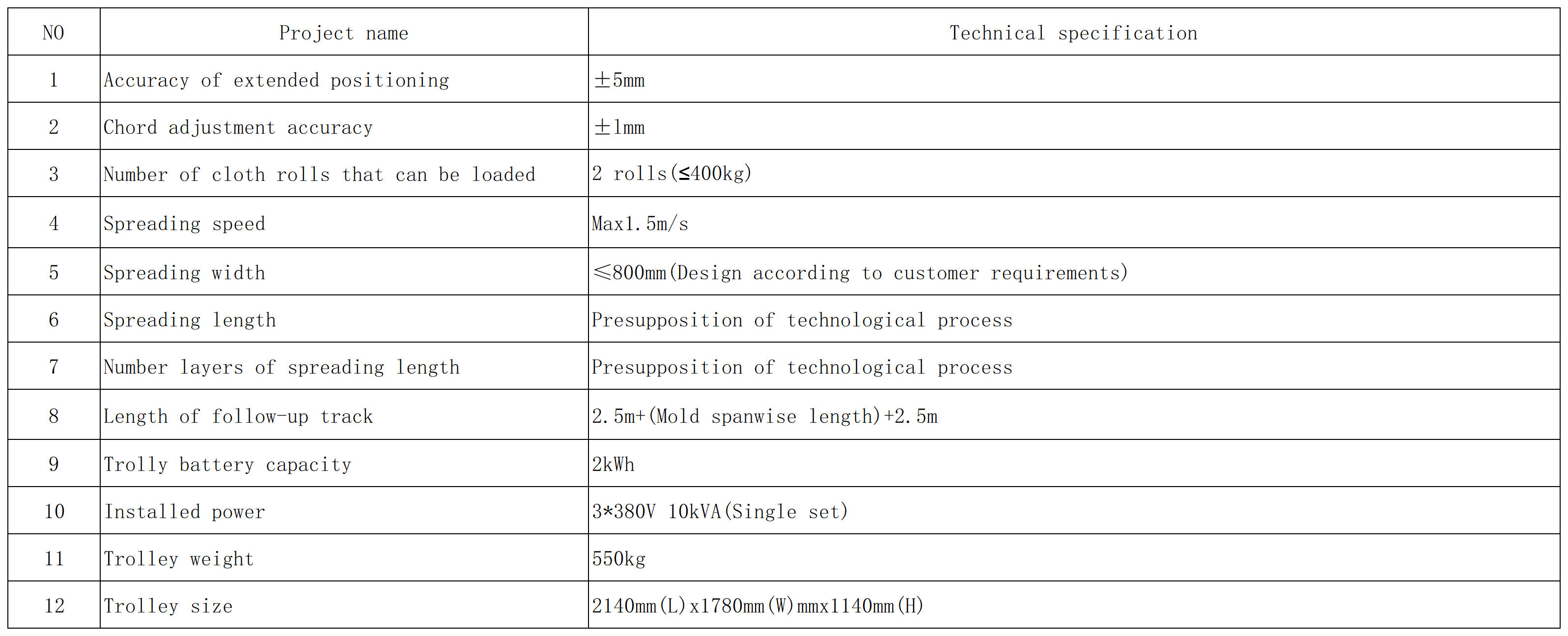

1.High positioning accuracy: precise correction and layering functions, chordal laying accuracy ≤ ± 2mm, spanwise positioning accuracy ≤ ± 5mm, layering adjustment range up to 100mm, and automatic cutting function can be optional.

2.Large climbing angle: up to 40 degrees, safe and reliable without slipping, suitable for use with any mold.

3.Automatically run according to the process formula: each step is accompanied by voice reminders, achieving perfect human-machine collaboration.

4.High spreading efficiency: double headed back and forth spreading, with a maximum speed of 2m/s and an average of 1.5m/s.

5.Large load capacity: can load 2 rolls of fabric, up to 400kg, with a maximum width of 800mm, reducing the number of fabric changes.

6.Less manpower: two people work together on one mold to complete the tasks of changing, pressing, and cutting fabrics, resulting in low labor intensity.

7.High safety performance: there is no risk of derailment during high-speed operation, and various sensor protections are equipped to ensure personal and equipment safety.

8.Equipped with sound and light alarms, voice prompts, intelligent calling during operation to improve operational efficiency.

9.The battery life of the paving cart is long, and it has the function of automatic charging at zero point.

10.Equipped with a dedicated cantilever crane: convenient for lifting fabric rolls, without relying on cranes, resulting in higher production efficiency.

11.Independent track: no need to modify the mold, small on-site modification workload, and fast delivery time.

12.Less vulnerable parts: simple maintenance and low operating costs.

13.Reserved MES system interface: information transmission and implementation of intelligent manufacturing.